theater seating system

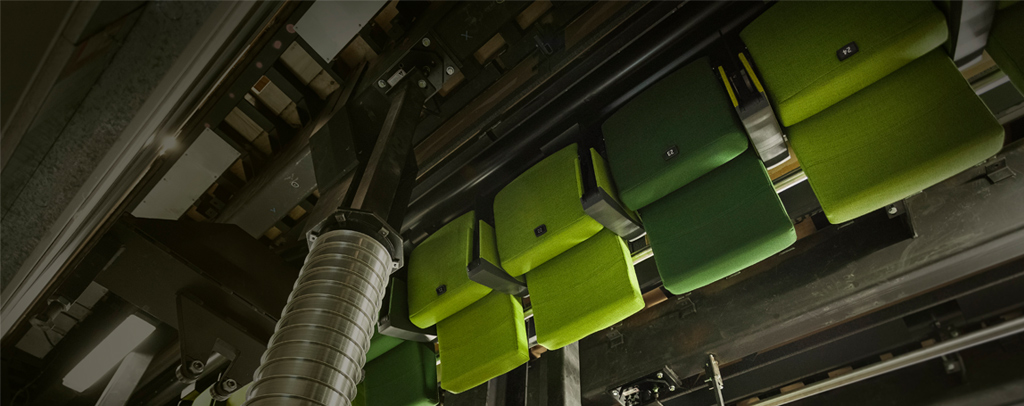

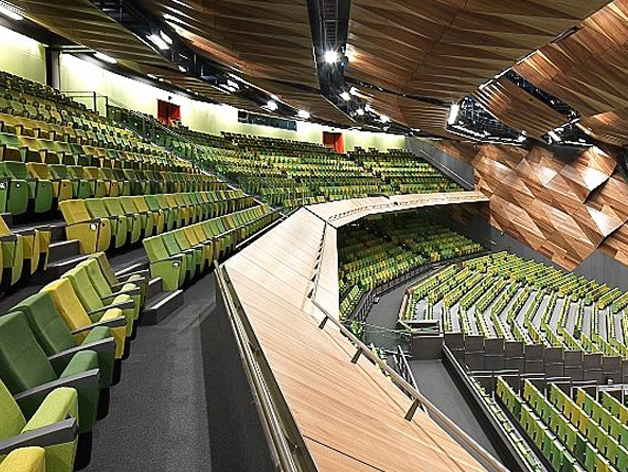

Leading contract furniture manufacturer Camatic was on a mission to design smart seating for the 5400 seat capacity Melbourne Convention Centre. The director of operations approached us to develop a seat that integrates with the center’s reconfigurable technical floor. The floor can be raised or lowered to allow for raised or staggered seating or flipped upside down, hiding the seats under it to allow for more floor space. The success of the Evoke theater seat helped Camatic secure key contracts for high profile venues.

Duration

18 months

industry

- safety and industrial

expertise

- industrial design

- mechanical engineering

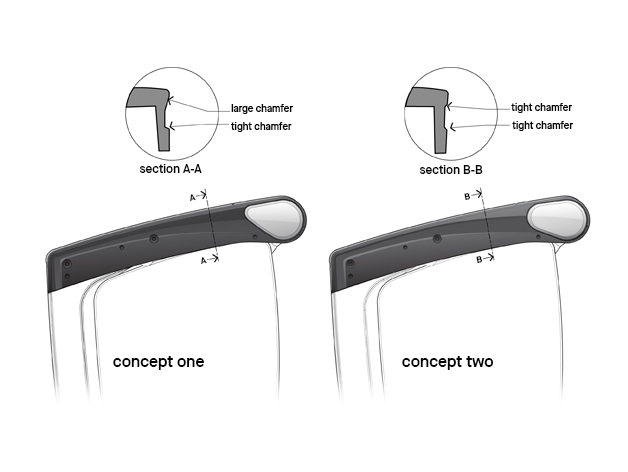

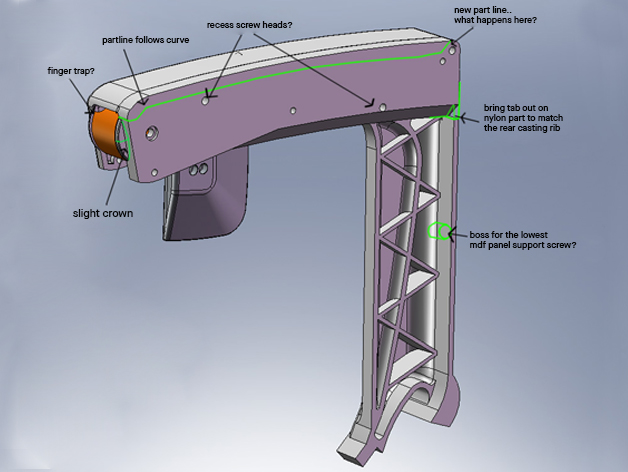

Our team detailed the Camatic Evoke theater seat with self-skinning polyurethane foam arms, that can be styled and textured and colored to coordinate with custom venue interior designs.

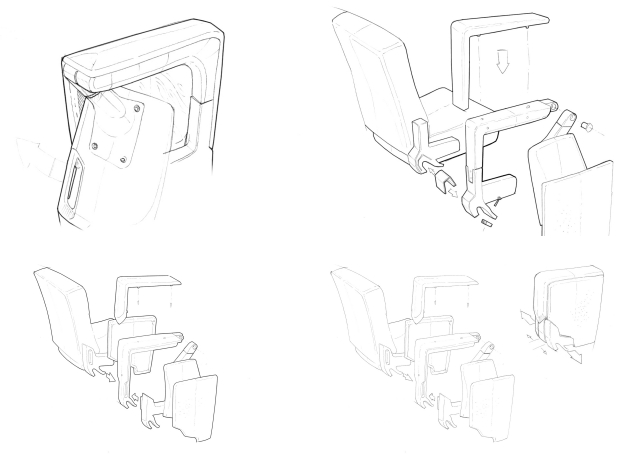

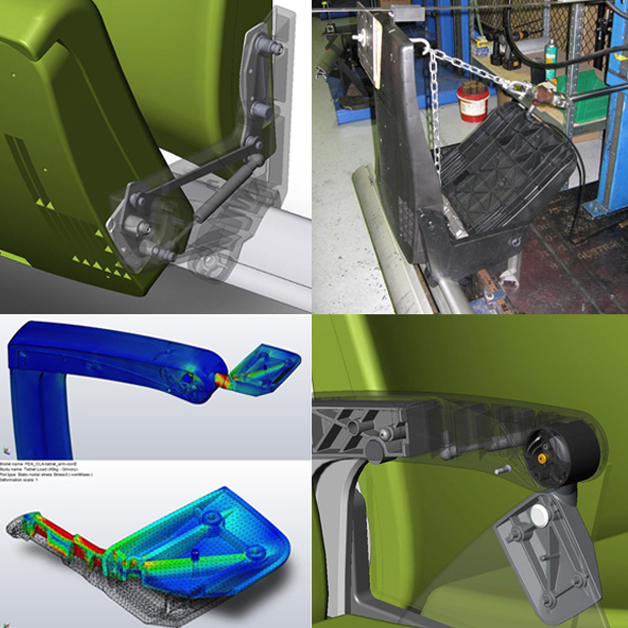

outerspace designers and engineers developed a beam mounting system that enables seat spacing at infinite locations along a row of seats. We replaced traditional gravity seat and back mechanisms with a reliable and enclosed silent gas-spring system to keep the seat folded, closed and quiet when inverted into the floor space. The design of the seating was tightly controlled to avoid interference with the floor during rotation.

Simplified and integrated single part injection molded row indicator lights were designed to save manufacturing time and costs. Seat padding is ergonomically contoured using specialized formulated foams for long term comfort.

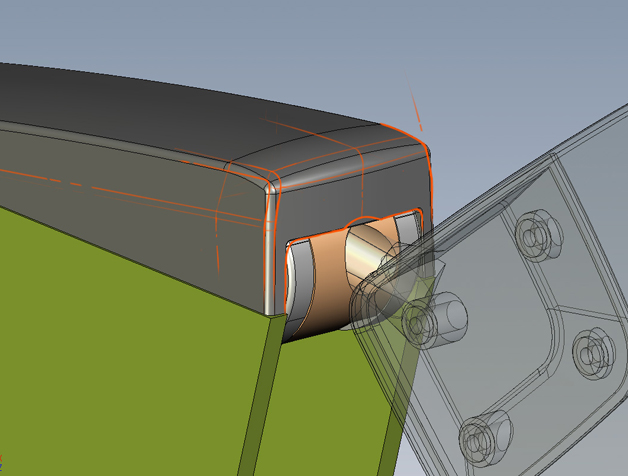

The upholstered seat cover panel hides an A3 sized fold out table and a table arm mechanism. We designed the table to be positioned below the armrest for comfortable use.

Our team engineered and tested all Evoke components for durability. The chairs are designed for disassembly, serviceability and long life. The covers are vandal resistant and removable for cleaning or replacement. All plastic components bear recycling code identification and comply with worldwide recycling standards.

Cost and weight reductions were achieved by optimizing component design and replacing some metal parts with engineering plastics. Computerized strength testing ensured strength on weight reduced parts. We ran rigorous endurance tests on rapid prototyped parts to validate results prior to mass production.

We developed a die-cast aluminum table bracket for extra strength, and a sophisticated mechanism incorporates a gas strut and articulating knuckle within a rotating cylinder that facilitates an easy, fluid motion of the table, counterbalancing the table mass even when the chair is inverted.

Our engineers designed an anti-panic deployment system where the table returns automatically to its home position when a person stands up quickly – a key safety feature for emergencies.

Managing Director, Comtruk