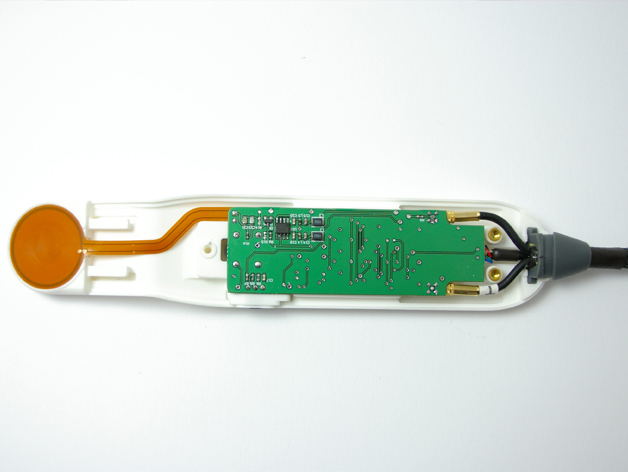

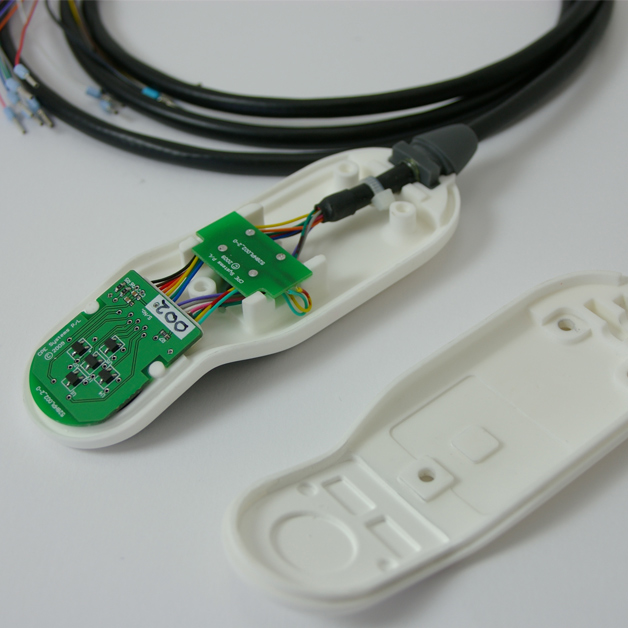

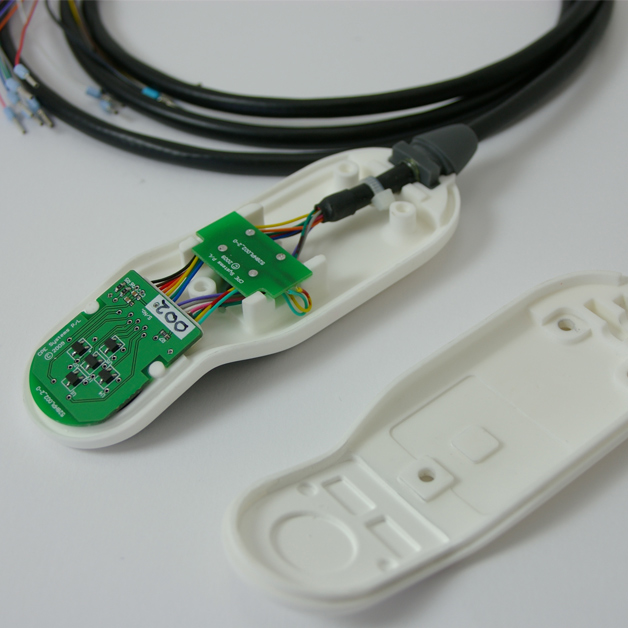

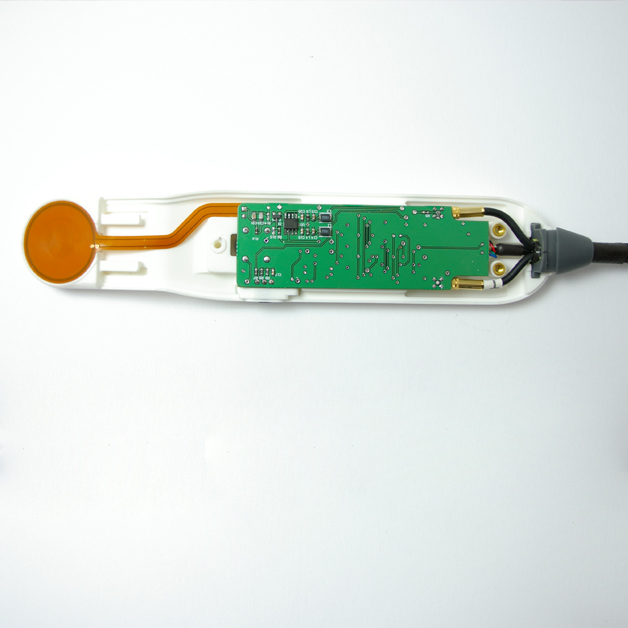

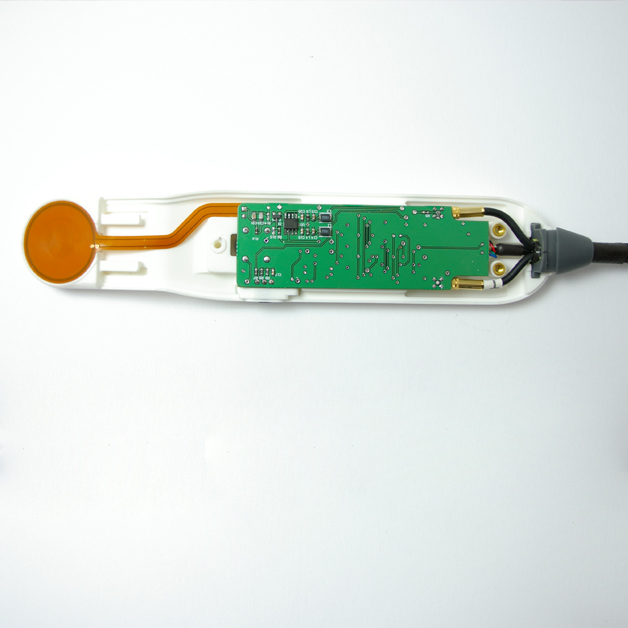

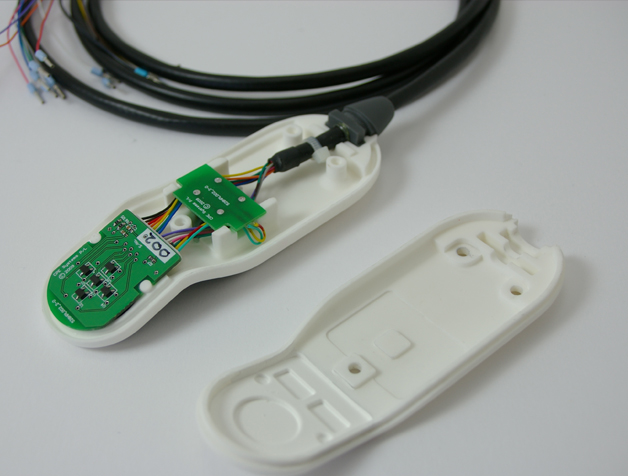

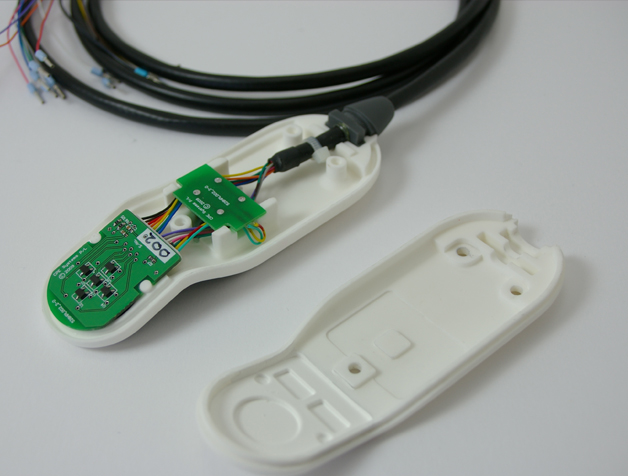

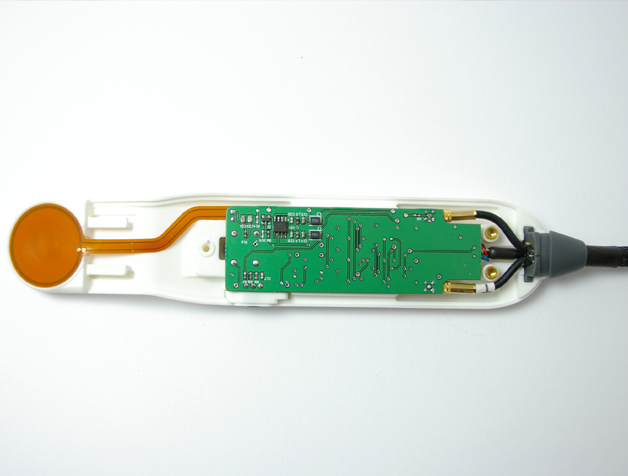

cochlear implant testing devices

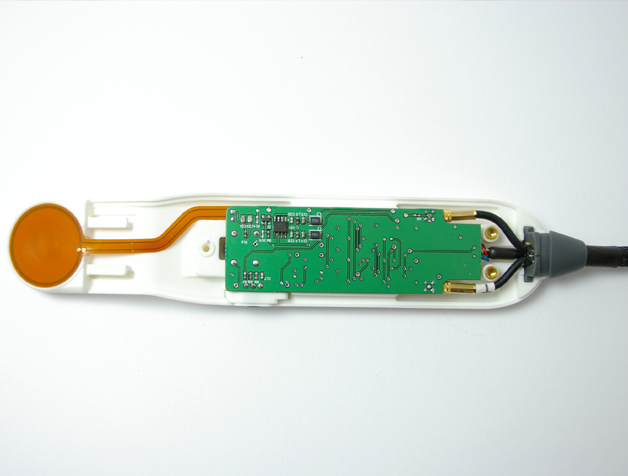

Implantable hearing device company Cochlear Ltd, needed to refine and develop a skin flap thickness tester and a coil tuning frequency tester to collect data about the performance of a recipient’s cochlear implant.

Duration

12 months

industry

- medical and scientific

expertise

- industrial design

- mechanical engineering

Cochlear had built rudimentary laboratory tools to conduct cochlear implant testing.

They needed these specialized tools to be refined and further developed for clinical use.

We worked with technical researchers at Cochlear and observed the test environment and the processes used at Cochlear clinics to see how clinicians use the devices and understand the patient experience.

We built and developed ergonomic mockups of the devices and tested them in the clinical environment.

Our designers and engineers refined and developed full electronic and mechanical prototypes.

The implant testing devices are used in-house at Cochlear headquarters in Australia, and at international Cochlear sites, to gather implant data to feed back into ongoing research and development.

Managing Director, Comtruk