call centre communication system

We collaborated with the CEO of Polaris Communications to develop the Soundshield call centre communication system using Polaris’ patented Soundshield technology, that prevents acoustic shock and long-term noise exposure. The communication system incorporates sound data that is exported for analysis to monitor and control noise levels in contact centres.

Duration

2 years

industry

- safety and industrial

expertise

- industrial design

- program and systems engineering

Recognition

iF award, Good Design Award

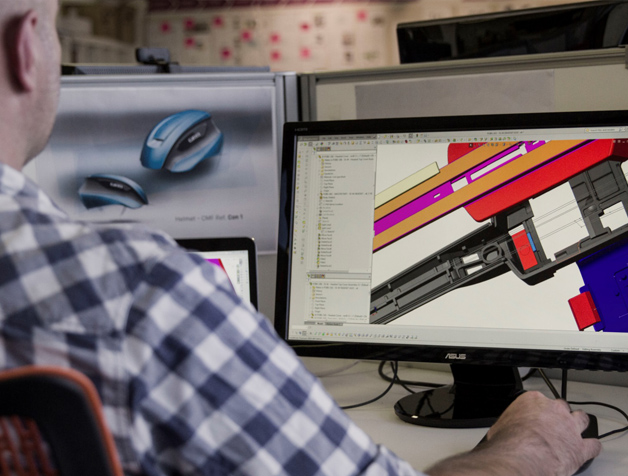

We worked with Polaris and strategized the system configurations that would be needed for the different markets they were targeting with their Soundshield technology. We leveraged this opportunity for Polaris, across a range of models with distinct feature sets and price points for different customers.

outerspace designers visited contact centres to analyze the user experience, observing operators engaging with customers and communications technology. Insights into desk environment, cable management, function use frequency and hierarchy, operator priorities, frustrations, training interventions, common errors and physical safety issues informed our development.

We used brainstorming and role playing to understand and develop better ways for contact centre staff to use the new system and excel at their jobs. This informed new headset system formats that solved common problems and made the user experience more enjoyable.

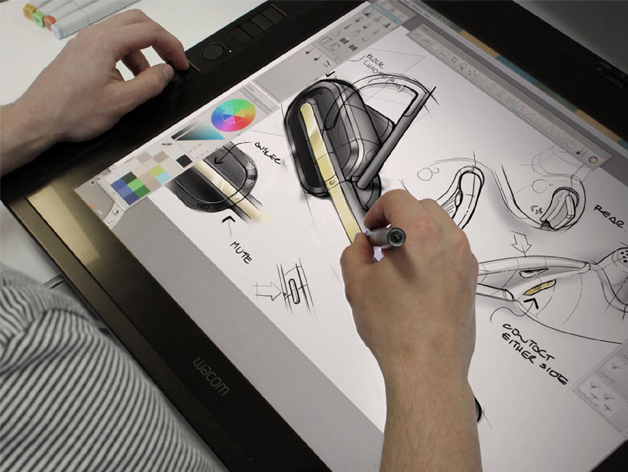

Our creative team explored various shapes and physical relationships between the product elements – the headset and dock, cable management, screen size, button design and color themes.

We realized that by utilizing a large touch screen we could integrate the ‘buttons’ into the screen for more flexibility in the interface, simplifying the features and achieving a cleaner aesthetic.

Early mock-ups of the Soundshield system established the size for the base station and screen, validated the design intent of the cable management design and highlighted the need for weight and rubberized feet in the base plate to overcome forces on the touchscreen. We designed an adjustable friction hinge system for the base for user adjustment to avoid ‘button bounce’.

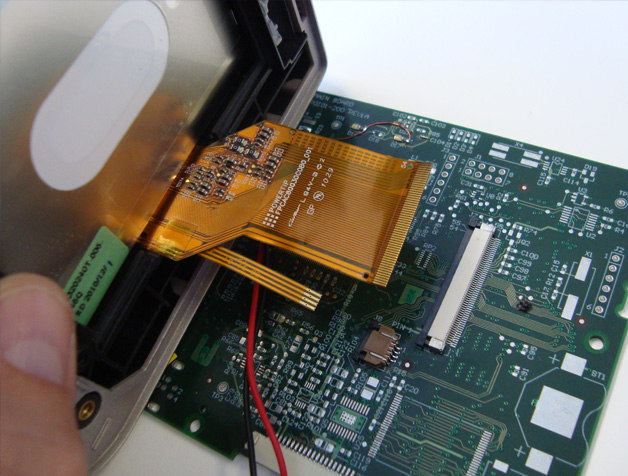

The head set is self-charging once in the dock. It needs to sit perfectly in the base to charge so we ensured the contact points are always easily engaged by engineering the geometry, and added a magnetic couple to make this an easy fit.

Our critical assessments of mock-ups established that too much or little motion in the unit detracted from optimal user experience. We made the screen angle adjustable to eliminate glare and designed the hinge to resist unintentional rotation.

We used anthropometric data and prototypes to assess the ergonomics and to define and develop the form of the headset and headset ear hook. It was important that the headset was comfortable for people to wear. We made sure it would fit across a wide range of head shapes and sizes.

We made the frequently-used mute button larger and positioned low on the screen with a color change function to indicate engagement.

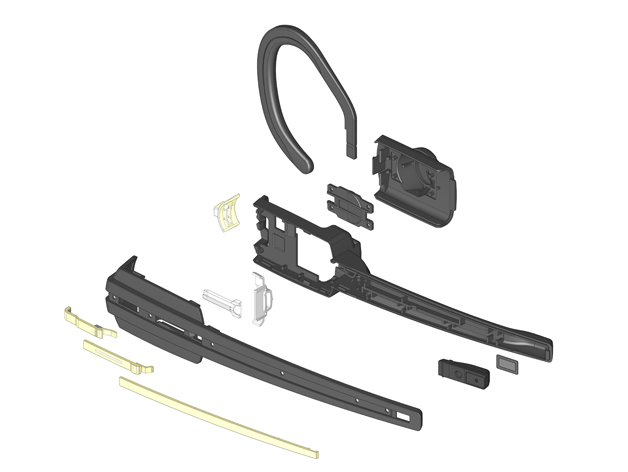

We engineered the full system, detailed, tested and analyzed the detailed plastic molded components and ensured the fit and function of the system was perfectly tolerance for high volume manufacture.

We managed and supervised the tooling and pre-production including quality control.

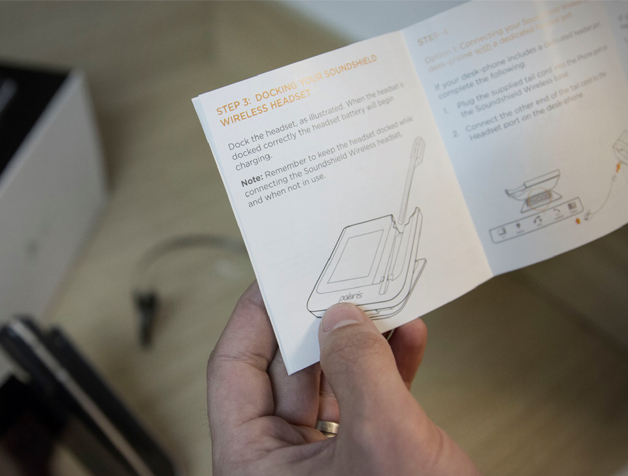

We designed and managed the production of the structural packaging and supporting material such as technical instruction manuals.

Managing Director, Comtruk