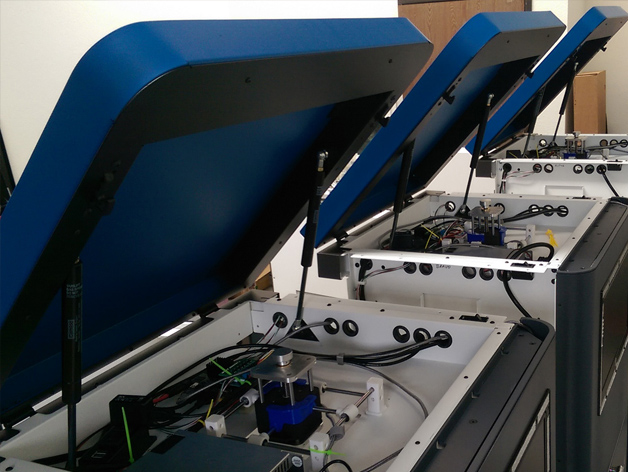

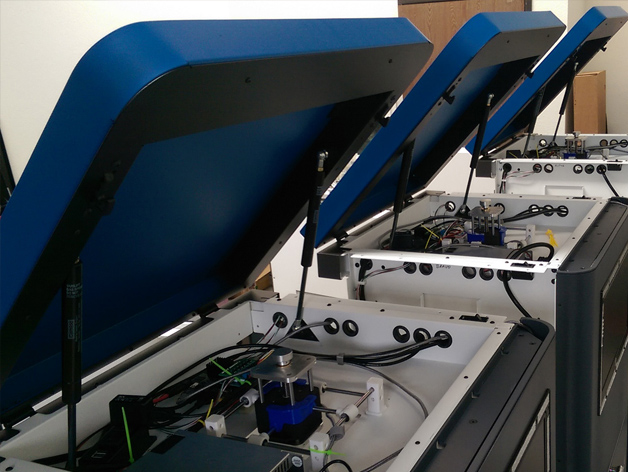

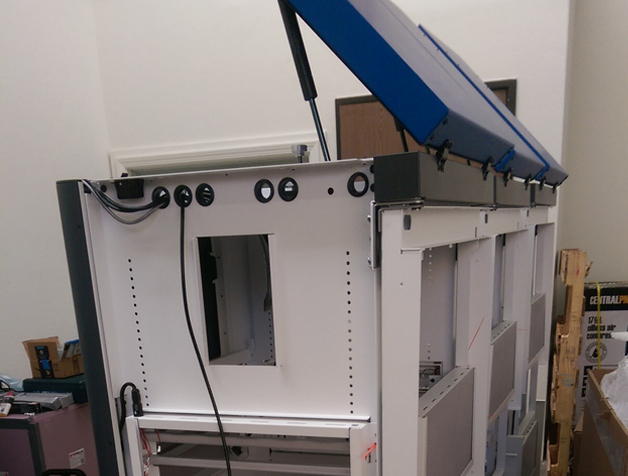

agricultural produce analyzer

The Agshift Inc analyzer system speeds up processing of harvested produce and sorts fresh product before it’s shipped to retailers, avoiding subjective human assessment of produce quality. It uses AI to analyze images of produce such as fruit, vegetables and nuts.

Duration

6 months

industry

- agriculture and environment

expertise

- mechanical engineering

- electronic engineering

- firmware design

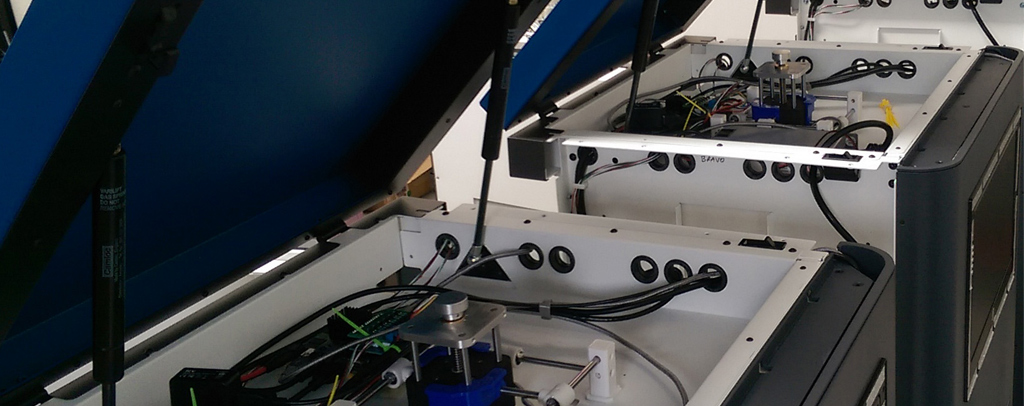

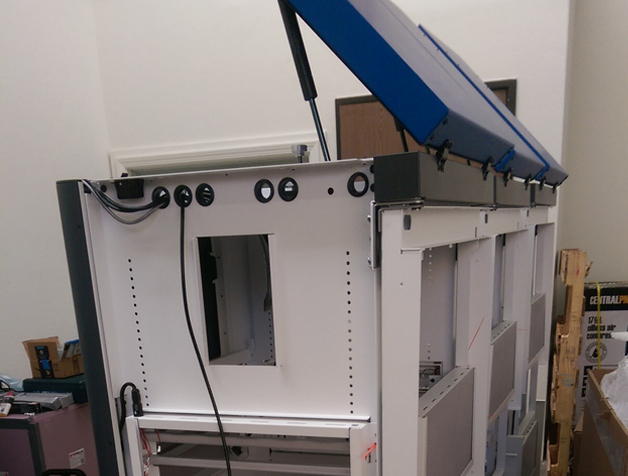

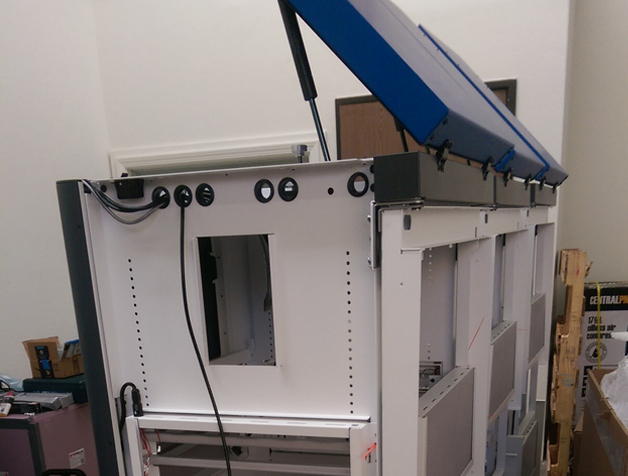

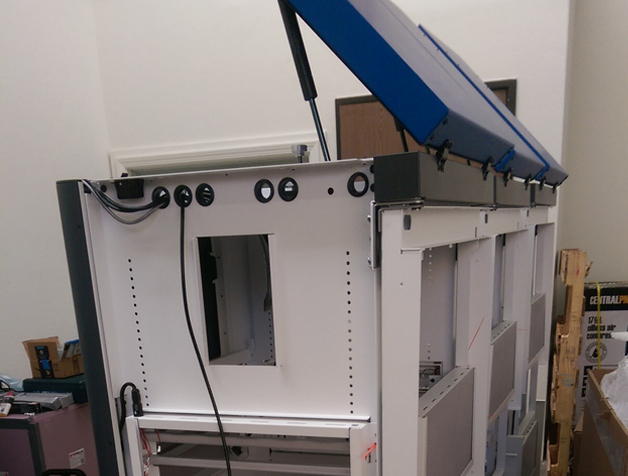

Agshift’s Chief Technical Officer engaged outerspace to develop an enclosure for the analyzer’s high definition cameras, custom PCB assemblies, lighting systems and power supply systems.

The enclosure needed to be engineered to operate in an agricultural warehousing environment, in varied humidity and temperature conditions. Produce sorting factors – weighing produce, auto-detecting produce type and developing a human-factors approach to the system with a touch screen GUI environment for operators was required.

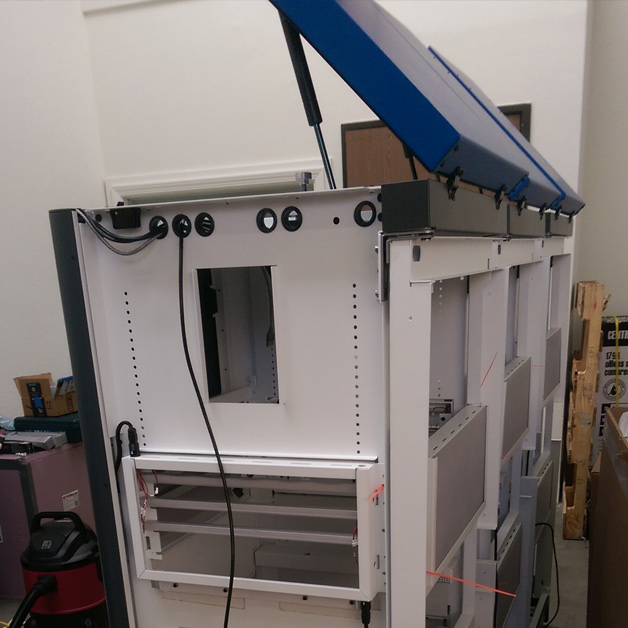

Our engineers determined the viability of these functions, and developed solutions to support implementation at the prototype stage, allowing for future implementation in the design architecture.

outerspace provided key strategic advice to Agshift regarding the future scope of the product and how to align it with customer needs. We used a traditional prototyping approach, isolating the electromechanical systems for weight sensing, imaging, AI and lighting setup to prove their efficacy.

Our strategic development approach highlighted problems early and set the ideal feature scope for the analyser. We used a technology integration approach to prove the analyser in all aspects in targeted field trials before larger implementation.

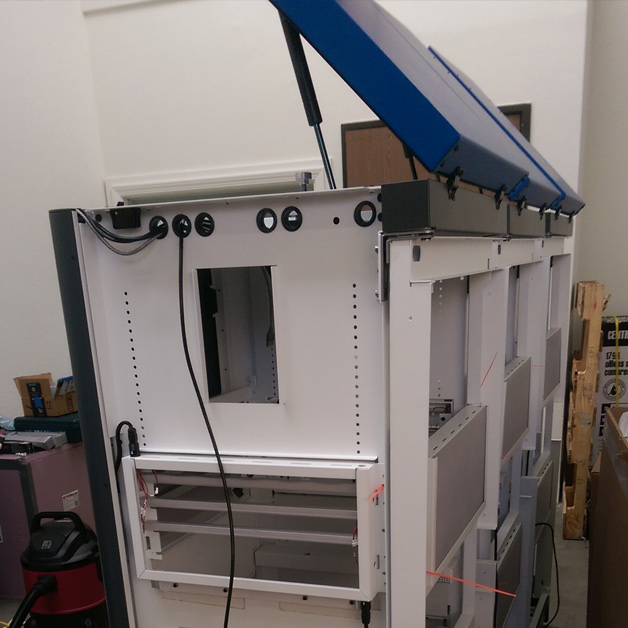

We researched AI systems and imaging processes, and from multiple prototype iterations helped Agshift correct and adjust their designs to support more applications, increasing the market application for their technology.

outerspace engineers assessed manufacturing tolerances and lighting abnormalities by designing adjustable systems to allow for field calibration of the analyser unit, while maintaining a low cost-of-goods target, avoiding significant redesign of the AI software systems.

outerspace engaged suppliers to design, build and validate prototype units on a low-volume production scale. This supply chain verification process was important in pre-build verification of components – from PCBA assembly, metalwork production, software integration, transport and electro-mechanical function verification all highlighted areas where improvements could be made before proceeding with mass-production at scale.

We accounted for real-world production tolerances while maintaining a viable cost-of-goods for analyser.

outerspace simplified construction techniques where possible, allowing for a wide range of calibration and adjustability, and worked with US-based contract manufacturers to determine best assembly practices and where testing and verifications processes could be improved and streamlined.

Managing Director, Comtruk