thermal camera

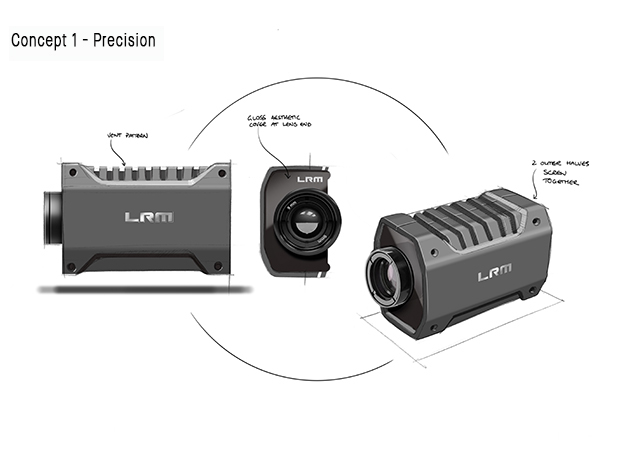

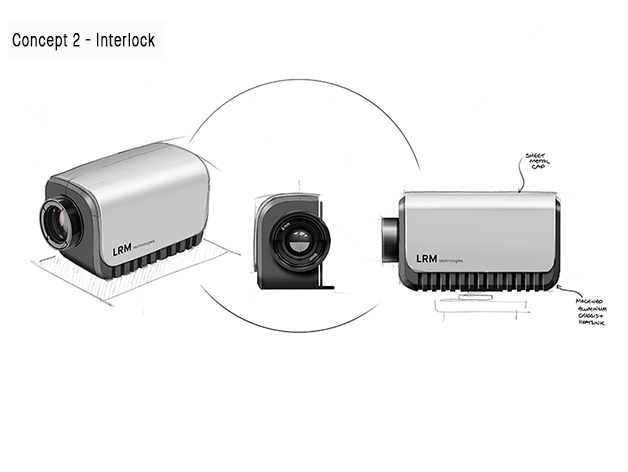

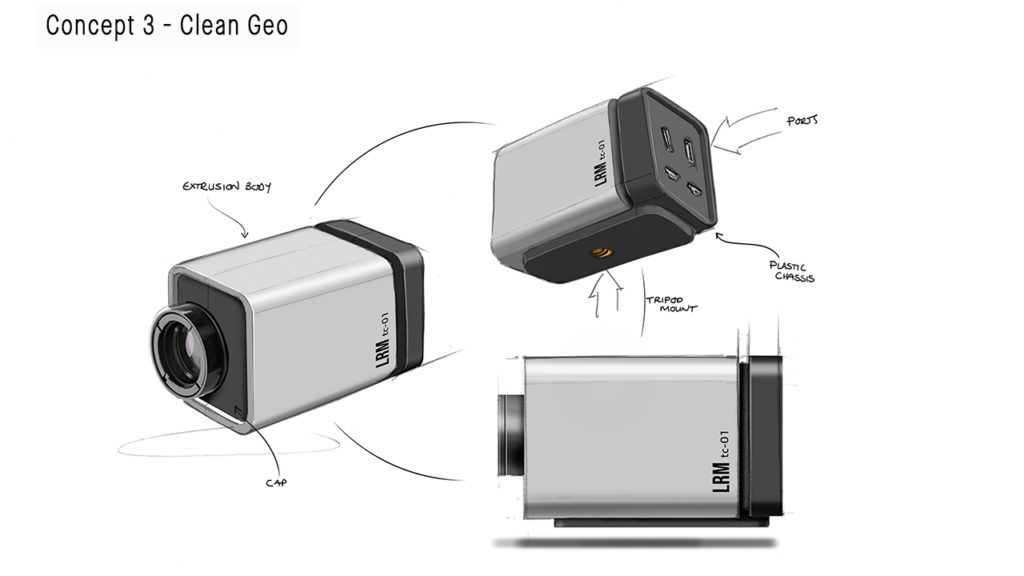

outerspace’s multidisciplinary team worked with the managing director of LRM Technologies and researchers at DST Group, to design the 1mK thermal camera that quantifies the stresses that cause metal fatigue in aircraft. LRM, a distributor of lasers and thermal imaging cameras, own the licence to apply Defence Science and Technology group software to a thermal camera product idea. LRM’s managing director had a very clear idea about what the DST Group technology could achieve and needed a clear product roadmap to a successful physical product outcome. outerspace collaborated with LRM and DST Group to clearly identify and plan the product format and pathway needed to create this revolutionary thermal camera.

Duration

18 months

industry

- safety and industrial

expertise

- electronic engineering

- firmware design

- industrial design

Recognition

Innovation Award – National Innovation Award – SME

outerspace and LRM worked together to obtain defense related grants to partially fund the development, and worked closely with DST Group to share the vision for the hardware development.

Our electronics and firmware experts, mechanical engineers and designers managed compliance testing and collaborated with DST Group to design the software interface. We ensured the electronics passed strict Electro Magnetic Compliance regulations in Australia and Europe.

outerspace developed the integrated thermal camera hardware and firmware with the software processing technology, resolving the technical challenges of integrating the thermal and visual camera modules into a bespoke electronics design and enclosure and integrated new internal module interfaces.

Our innovative design utilizes emerging technologies such as compact, low power longwave infrared, USB 3.1 and thermoelastic stress analysis algorithms. 1mK has an integrated visual camera for identifying a sample in its view such as a part of an aircraft fuselage. A thermal sensor captures thermal images of the metal undergoing stress and processing software analyzes the thermal sensor data, creating a resultant digital stress map of the sample.

The thermal camera enables superior structural performance sensing with its advanced features. It supercedes current technology in testing in the research, aerospace, defense and structural inspection markets with a powerful combination of accuracy, size and cost.

The camera was launched under a new 1 milliKelvin brand, representing the unrivalled sensitivity and software solutions it can achieve. One milliKelvin equals 1/1000th (0.001) of one degree celsius, which the camera is able to resolve.

Managing Director, Comtruk